Main: (909)595-1334 / FAX: (909)595-6411 / Sales@caltoolgrind.com

Main: (909)595-1334 / FAX: (909)595-6411 / Sales@caltoolgrind.com

Download Line Card

Main Line: 909 595 1334 / RFQ's to: sales@caltoolgrind.com

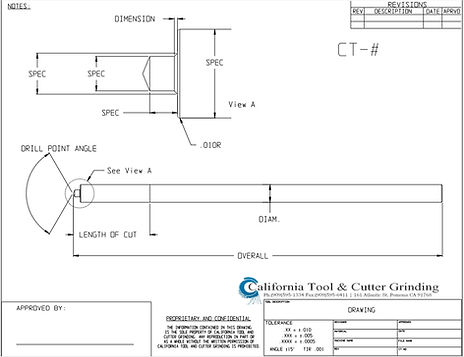

CUSTOM TO PRINT TOOLS, MADE TO PRINT SPECIFICATIONS

MADE WITH YOUR DESIRED:

- Diameter

- Length of cut

- Neck Length/LBS,

- Radius,

- Helix Angle

- Shank Diameter

- Diameter and length tolerances, etc.

- Geometry and coating

REQUEST A QUOTE:

In need of a Per-Print custom cutter. We understand that each customer can require cutting tools specific to their individual needs and applications. We're offer some of the quickest lead-times in the industry for time sensitive projects. Simply submit your drawing along with any other helpful information e.g. tool coating, tolerances, etc. and we'll respond promptly to your request. Send info to Sales@caltoolgrind.com

BUILT TO YOUR SPECIFIC REQUIREMENTS:

Each shop differs from one another with different machines, set-ups, speeds and feeds, materials they're machining, and methods of operation. This results in cutting tools developed over years that vary in size, geometry, and coating. We've consistently been able to meet our customers strict callouts on prints with the tightest tolerances available for cutting tools. Our team of experienced CNC operators, along with our rigorous inspection process guarantees our tools are developed with geometrical consistency performing to expectation and with the longest tool life possible.

PROVIDE OR COORDINATE WITH US TO DEVELOP A TOOL PRINT TO CERTIFY YOUR CALIFORNIA TOOL CT#

Our tooling engineers and sales staff coordinate with hundreds of companies every year to plan, design, and manufacture tailored carbide cutting tools specific to their companies operations, material being machined, and machine type and capability. No two operations are exactly the same resulting in many variations in tool size, geometry, unique forms, tool coating, etc.

Custom to print cutters manufactured:

4FL Form Step Reamer, with coolant through side holes

2 flute Step Form Cutter

4 Fl Lollipop Cutter

Pencil Mill

2F Flute custom end mill

with large Radius/Necked

Chamfer Mill

Long Reach Step Reamer

Form Radius Cutter

Drill Countersink Combo

TO SUBMIT YOUR REQUEST:

To Submit your RFQ you can call us at our main number: (909) 595-1334 or email us at sales@caltoolgrind.com